visit and choose our best services

Projense Systems to explore our industry-leading ERP solutions for Alloy Steel. Optimize production, inventory, and quality control with seamless integration and real-time insights.

In the dynamic Alloy Steel industry, managing raw materials, melting, rolling, heat treatment, quality control, and dispatch while meeting diverse customer specifications can be challenging. Projense System provides a smart, fully integrated ERP solution designed specifically for the Alloy Steel sector to streamline operations, improve efficiency, and maximize profitability.

Working in the Alloy Steel industry is not easy. You have to manage many steps like raw materials, melting, rolling, and heat treatment. On top of that, every customer wants something different, which makes it harder to keep things smooth and accurate.

Projense Systems offers an ERP made just for this. It helps you handle all your work in one place, reduce mistakes, check quality at every step, and deliver the right product on time. It's a smart way to work better and grow faster.

Tailored for Alloy Steel Manufacturing

Designed to manage every stage—from raw material procurement, melting, rolling, heat treatment, and finishing to dispatch—ensuring a seamless workflow.

Real-Time Production & Process Control

Tracks live production metrics, minimizes downtime, and optimizes furnace, rolling mill, and finishing operations for maximum efficiency.

Advanced Quality Assurance

Ensures compliance with ASTM, ISO, and other industry standards, reducing defects and enhancing product reliability.

Cost Optimization & Waste Reduction

Smart inventory control and production planning help minimize material wastage, lower operational costs, and boost profitability.

Integrated Supply Chain & Logistics

From raw material sourcing to finished product dispatch, gain full visibility and improve delivery timelines with real-time tracking.

Scalable & Future-Ready

Whether you're a mid-size manufacturer or a large-scale alloy steel producer, Projense ERP scales with your business needs.

Multi-Platform Accessibility

Access your ERP anytime, anywhere—on Web, Cloud, On-Premises, and Mobile—for better control and decision-making.

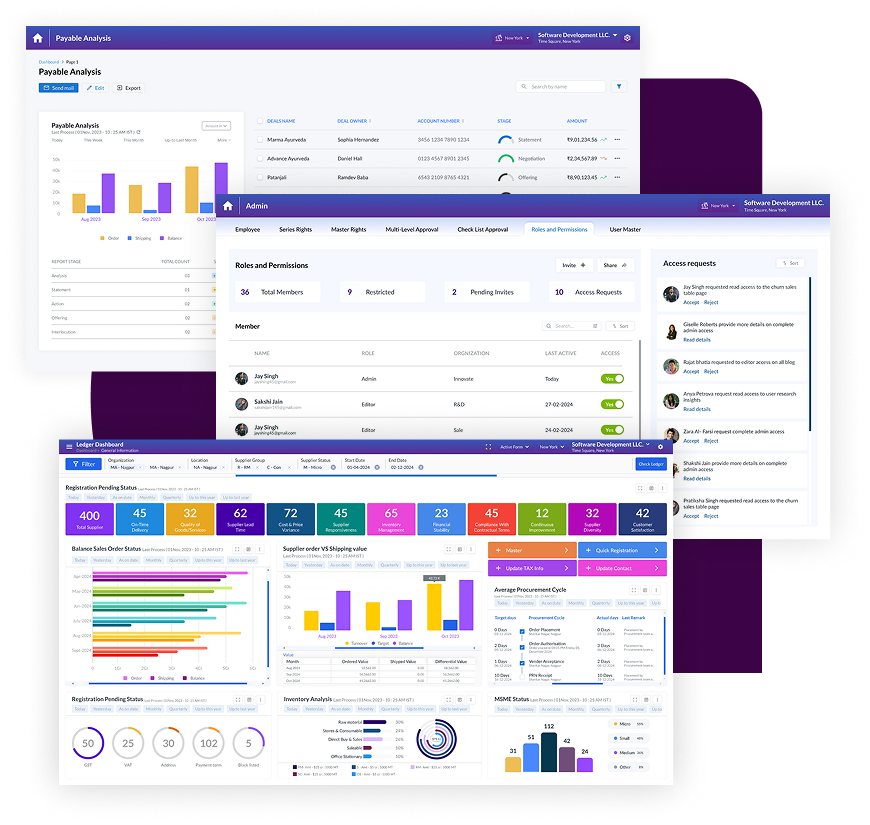

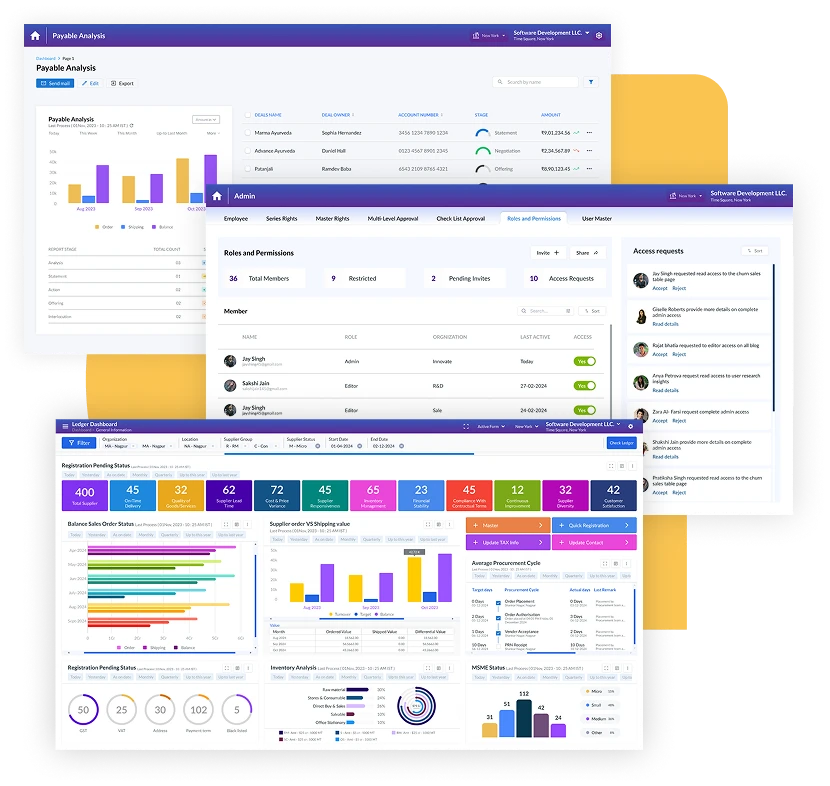

Business Intelligence & Analytics

AI-powered insights and custom dashboards enable data-driven decisions, improving overall productivity and competitiveness.

Efficient tracking of alloys, scrap, and additives for precise production control.

Seamless Raw Material Management

Automated scheduling of melting, rolling, and heat treatment processes to reduce downtime.

Optimized Production Planning

Real-time monitoring and compliance with industry standards (ASTM, ISO, etc.).

Enhanced Quality Control

Smart stock management with real-time material tracking and automated procurement.

Inventory & Supply Chain Efficiency

Minimize waste, control expenses, and maximize resource utilization.

Cost Optimization & Profitability

Streamlined order fulfilment with real-time shipment tracking and invoicing.

Integrated Dispatch & Logistics

Data-driven insights for better decision-making and production efficiency.

Business Intelligence & Analytics

Available on Web, Cloud, On-Premises, and Mobile for real-time control.

Multi-Platform Accessibility

Meet Our Mission

At Projense Systems, we specialize in seamless ERP implementations for the Alloy Steel industry, optimizing production, inventory, and quality control. Our solutions enhance efficiency, streamline operations, and provide real-time insights for smarter decision-making.

Deep Industry Knowledge

.png)

Customized Solutions

.png)

Proven Implementation Process

.png)

Ongoing Support

Projense Systems is committed to delivering future-ready, customer-centric software solutions with an unwavering focus on quality, innovation, and excellence in software development and implementation.

Get in touch today for a personalized software implementation consultation with our expert team! Let’s transform your ideas into powerful, innovative solutions and drive your success forward.

Join the other exporters and importers who get the latest news, tips and insights from international trade professionals.