Stainless Steel Billets

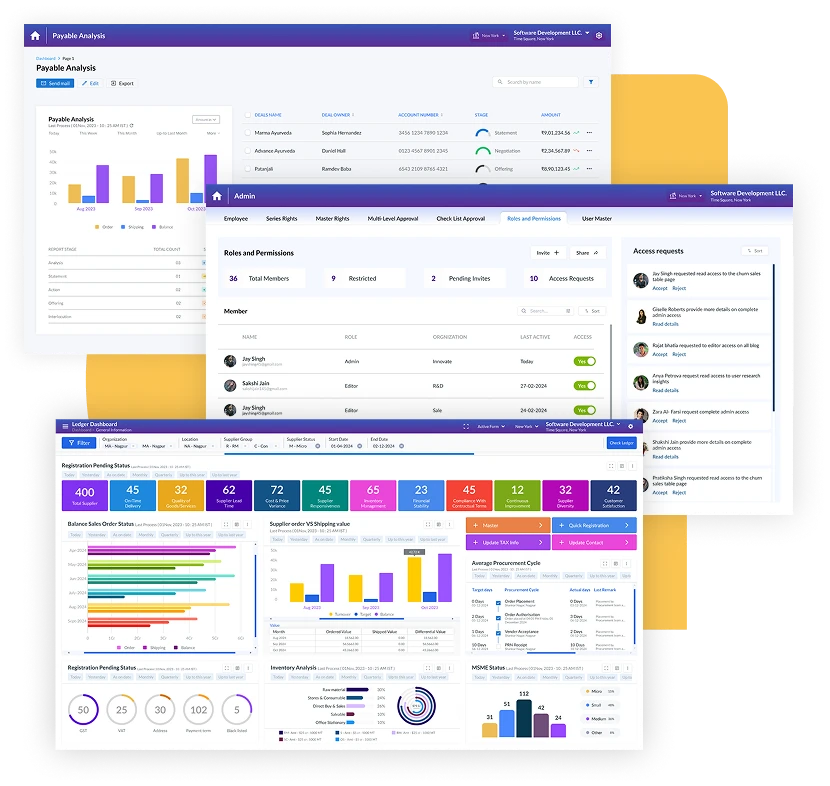

Projense ERP Systems provides a powerful, industry-tailored ERP solution for managing the complexities of Billets production. Our system enables real-time monitoring, precise control of production parameters for inventory control and seamless integration across operations, resulting in improved efficiency, consistent product quality, and higher customer satisfaction.

production Technical parameters

| Size |

Type |

Grades |

| Equipment |

Billet |

200 series |

| Radiation Detection System |

Slab |

300 series |

| Furnace |

|

400 series |

| AOD |

|

Electrode Grades |

| Gas Plant |

|

Duplex and Others |

| Rolling Mill |

|

Duplex and Others |

Stainless Steel Wire Rods

Projense ERP Systems provides a powerful, industry-tailored ERP solution for managing the complexities of Wire Rods production. Our system enables real-time monitoring, precise control of production parameters for inventory control and seamless integration across operations, resulting in improved efficiency, consistent product quality, and higher customer satisfaction.

production Technical parameters

| Size |

Grades |

| Wire Rod |

ASTM |

|

DIN/EN |

Stainless Steel Wires

Projense ERP Systems provides a powerful, industry-tailored ERP solution for managing the complexities of Wires production. Our system enables real-time monitoring, precise control of production parameters for inventory control and seamless integration across operations, resulting in improved efficiency, consistent product quality, and higher customer satisfaction.

production Technical parameters

| Size Ranges |

Grades |

| 0.80 – 1.80 mm |

ASTM |

| 1.8 – 8.0 mm |

DIN/EN |

| 8 – 20.0 mm |

Electrode Grades |

Stainless Steel Flats

Projense ERP Systems provides a powerful, industry-tailored ERP solution for managing the complexities of Flats production. Our system enables real-time monitoring, precise control of production parameters for inventory control and seamless integration across operations, resulting in improved efficiency, consistent product quality, and higher customer satisfaction.

production Technical parameters

| Grades |

Technical Parameters |

| IS 2062 |

Width & Thickness |

| ASTM A36 |

Length |

| EN 10025 |

Tolerance |

| SAE 1010 / 1020 / 1045 |

Straightness |

| Austenitic |

Flatness |

| Ferritic |

Edge Condition |

| Martensitic |

Surface Finish |

Stainless Steel Round Bars

Projense ERP Systems provides a powerful, industry-tailored ERP solution for managing the complexities of Rounds Bars production. Our system enables real-time monitoring, precise control of production parameters for inventory control and seamless integration across operations, resulting in improved efficiency, consistent product quality, and higher customer satisfaction.

manufacturers can reduce rework, improve compliance, and deliver consistent quality on time.

production Technical parameters

| Size Range |

Grades |

Length |

| 36-110 mm |

AISI |

3-6.5 m |

Stainless Steel BRIGHT BARS

Projense ERP Systems provides a powerful, industry-tailored ERP solution for managing the complexities of Bright Bars production. Our system enables real-time monitoring, precise control of production parameters for inventory control and seamless integration across operations, resulting in improved efficiency, consistent product quality, and higher customer satisfaction..

production Technical parameters

| Type |

Size Range |

Grades |

| Round |

5-16 mm |

ASTM |

| Square |

5-12 mm |

DIN/EN |

| Hexagon |

5-12 mm |

|

Stainless Steel Rebars

Projense ERP Systems provides a powerful, industry-tailored ERP solution for managing the complexities of Rebars production. Our system enables real-time monitoring, precise control of production parameters for inventory control and seamless integration across operations, resulting in improved efficiency, consistent product quality, and higher customer satisfaction.

production Technical parameters

| Size Range |

Grades |

| 6 – 32 mm |

AISI |

Stainless Steel FASTENERS

Projense ERP Systems provides a powerful, industry-tailored ERP solution for managing the complexities of Fasteners production. Our system enables real-time monitoring, precise control of production parameters for inventory control and seamless integration across operations, resulting in improved efficiency, consistent product quality, and higher customer satisfaction.

production Technical parameters

| Grades |

Dimensional Parameters |

| IS 1367 |

Size Range |

| ASTM A307 |

Threads |

| SAE J429 |

Thread Fit |

| Austenitic |

Length Tolerances |

| Martensitic |

Head Shapes |

| Duplex/Super Duplex |

Point Types |