Managing the production of pipes requires accuracy in scheduling production, ensuring quality, and using raw materials. The ERP from Projense Systems streamlines operations in the pipe industry by improving inventory control, automating workflows, and guaranteeing smooth process integration. Our solution increases productivity, lowers expenses, and produces higher-quality products with real-time production tracking, waste minimisation, and compliance management.

Producing pipes demands precision in scheduling, raw material usage, and quality control. Projense ERP System empowers pipe manufacturers with real-time production tracking, automated workflows, and integrated inventory and compliance management—boosting productivity, reducing waste, and ensuring consistent product quality.

Pipe manufacturers who want to streamline production, reduce material waste, and improve quality control can benefit from Projense ERP. Our solution is built for the pipe industry, giving you better control over operations, higher efficiency, and improved profits..

Use Projense ERP to streamline the entire pipe production process, from the receipt of raw materials to the last shipment. Gain real-time control, improve batch consistency, and ensure on-time delivery with a system built for precision and performance.

Lead & Inquiry Management:

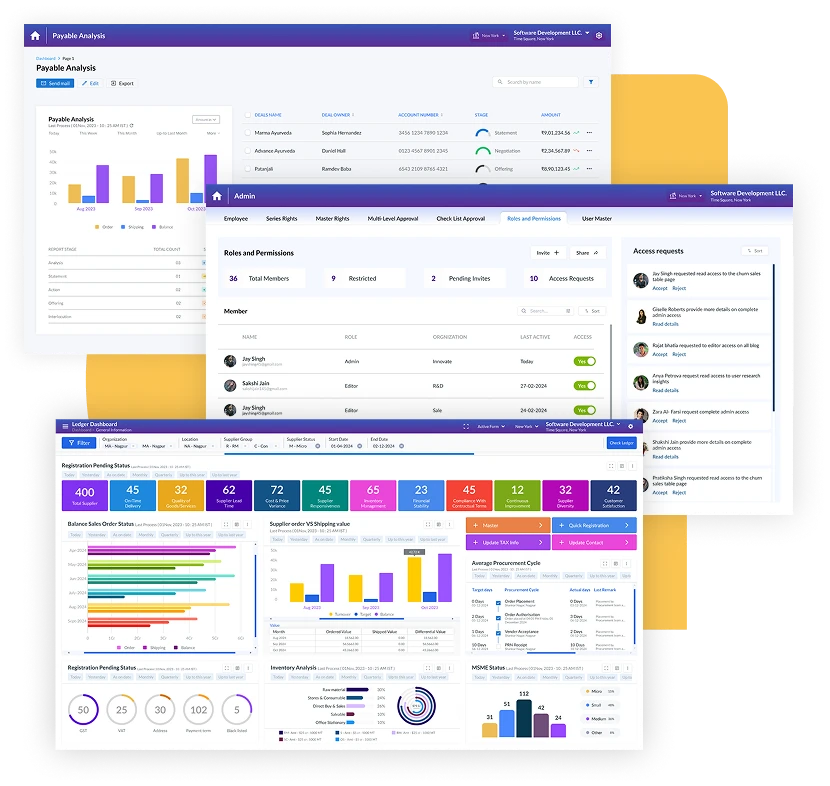

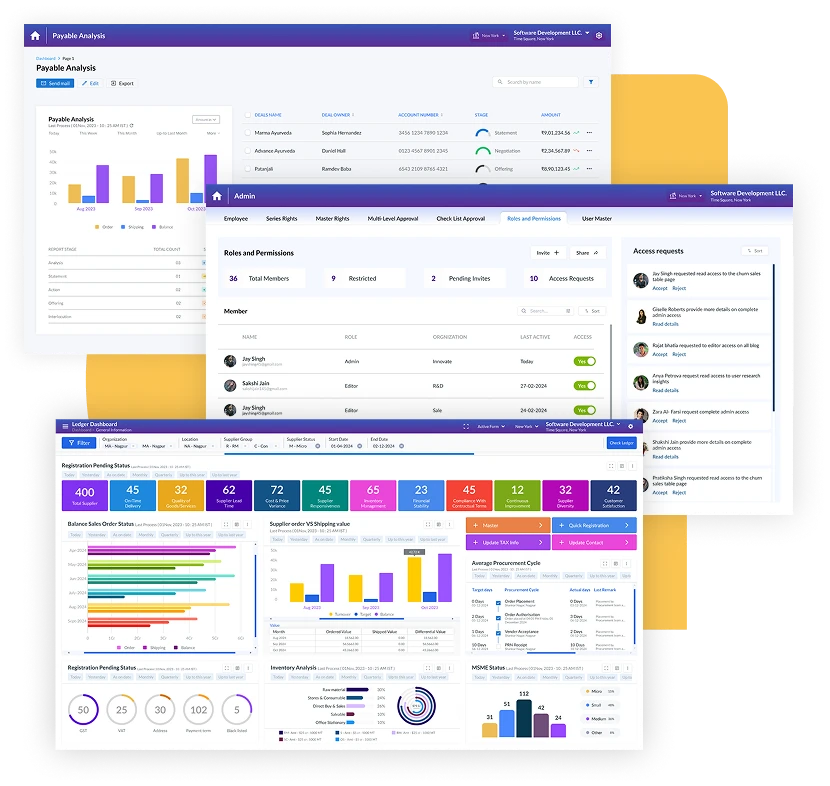

Track inquiries based on pipe type, size, and target segments like agriculture or infrastructure, while managing lead sources and follow-up status for better sales visibility.

Quotation Management:

Generate multi-size and specification-based quotations, manage version control with approval workflows, and access historical rate comparisons for smarter pricing decisions.

Order & Dispatch Tracking:

Maintain customer-specific order history and revisions, send dispatch alerts via email/SMS, and confirm artwork or specifications for personalized branding.

Complaint & After-Sales Support:

Log complaints such as cracks, pressure failures, or fitting issues, track resolutions based on SLAs, and manage replacements or credit note issuance efficiently.

Marketing Campaigns:

Run targeted campaigns by region or sector like irrigation and housing, track trade show leads and dealer networks, and manage bulk email outreach with follow-up tools.

Customer Analytics:

Analyse customer-wise revenue and profitability, monitor sales funnel performance, and integrate seamlessly with ERP for complete business visibility and decision-making.

Production Planning & Control

BOM & Recipe Management

Quality Management

Inventory & Material Management

Tool & Die Management

Sales & Order Management

Job Costing & Estimation

Maintenance Management

Finance & Accounting

HR & Payroll

Compliance & Reporting

Your trusted guide -

Projense ERP: Your compass in the dynamic ethanol market. Streamline operations, ensure compliance, and optimize profitability. Navigate feedstock volatility and regulatory hurdles with ease. Empowering your ethanol business for sustainable growth.

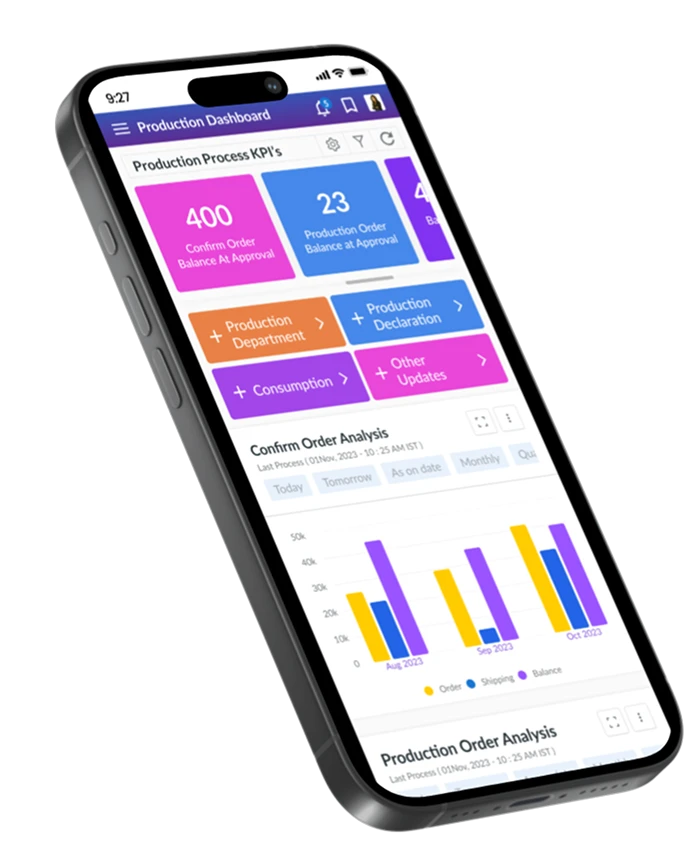

Production Planning and Scheduling

Inventory Management

Quality Assurance

Cost Control

Sales and Customer Relationship Management (CRM)

Data Analytics and Reporting

Traceability and Compliance

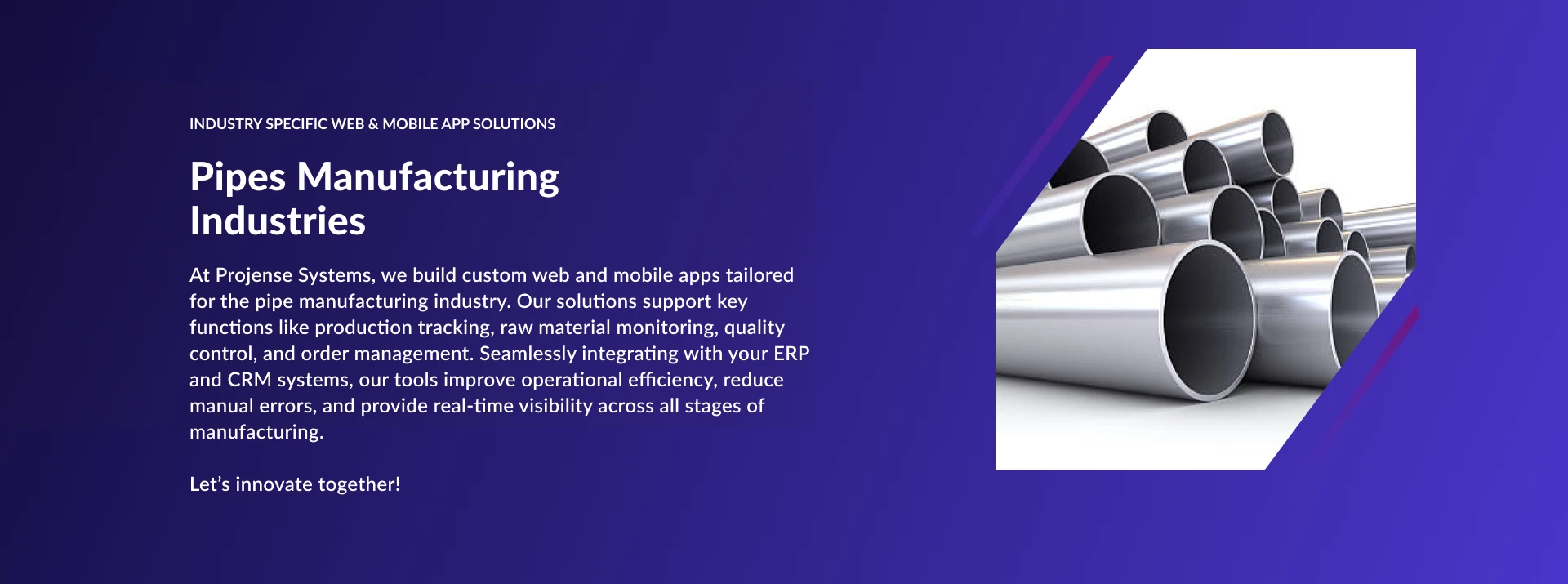

The Pipe manufacturing industry plays a vital role in global infrastructure, serving key sectors such as construction, water supply, oil and gas, agriculture, and industrial development. With rising demand for urban development, sustainable water systems, and energy transport, manufacturers are under pressure to deliver durable, high-performance pipes that meet varied technical and regulatory requirements—faster and more efficiently than ever before.

This industry faces its own set of challenges, including complex production processes, fluctuating raw material prices, strict compliance standards, and highly customized customer demands. Navigating these complexities while ensuring quality and profitability demands more than traditional systems—it calls for intelligent, integrated solutions that bring visibility, control, and agility to every stage of manufacturing.

Projense ERP helps pipe manufacturers run their operations more smoothly, keep quality under control, and respond quickly to changing customer needs—making it easier to stay efficient and grow the business.

Industry-Specific Customisation

Made to satisfy the particular requirements of the pipe manufacturing process, which includes coating, welding, and extrusion.

Advanced Production Planning

This ensures smooth operations by automating scheduling and resource allocation.

Optimal stock levels

For both raw materials and completed goods are guaranteed by real-time inventory tracking.

Integrating QA procedures

To satisfy client demands and industry standards is known as quality control and compliance.

.webp)

Improved supply chain management

Increases the effectiveness of procurement, logistics, and vendor coordination.

Waste Reduction & Cost Optimisation

This approach lowers material waste and increases cost effectiveness.

Seamless process integration

Production, sales, procurement, and finance are all connected for more efficient operations through.

Real-time insights for improved

Operational control and strategic planning are provided by data-driven decision making.

Scalable & Flexible Solution

This ERP solution's modular and customisable features allow it to grow with the company.

Projense Systems is committed to delivering future-ready, customer-centric software solutions with an unwavering focus on quality, innovation, and excellence in software development and implementation.

Get in touch today for a personalized software implementation consultation with our expert team! Let’s transform your ideas into powerful, innovative solutions and drive your success forward.

Join the other exporters and importers who get the latest news, tips and insights from international trade professionals.