.webp)

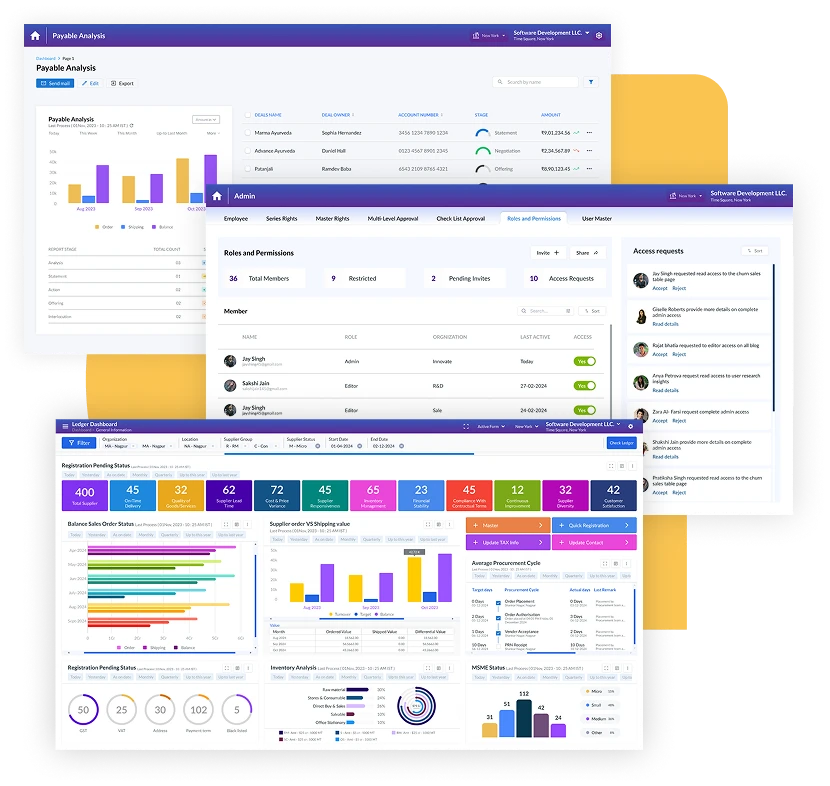

Simplify Processes, Increase Production with Projense ERP Designed for Accuracy in Extrusion Processes.

ERP Program for Extrusion Management Extrusion process optimisation necessitates exact control over production scheduling, material usage, and quality requirements. By automating workflow, boosting process efficiency, and improving inventory tracking, Projense Systems' ERP is made to simplify extrusion operations. Our solution guarantees increased productivity, cost savings, and superior product quality through real-time monitoring, waste reduction tactics, and seamless departmental integration.

.webp)