Ferro Alloys Industry ERP Solution

At Projense Systems Pvt. Ltd., we understand the complexities of the ferro alloys industry, where quality parameters, batch consistency, and grade-specific inventory management with are critical for maintaining operational efficiency with real-time inventory accounting, and integration with third-party systems. and meeting customer demands. With our All-in-One ERP Software, specifically designed for the ferro alloys industry, we empower businesses to streamline operations, ensure compliance, and deliver superior quality—all while driving growth and profitability.

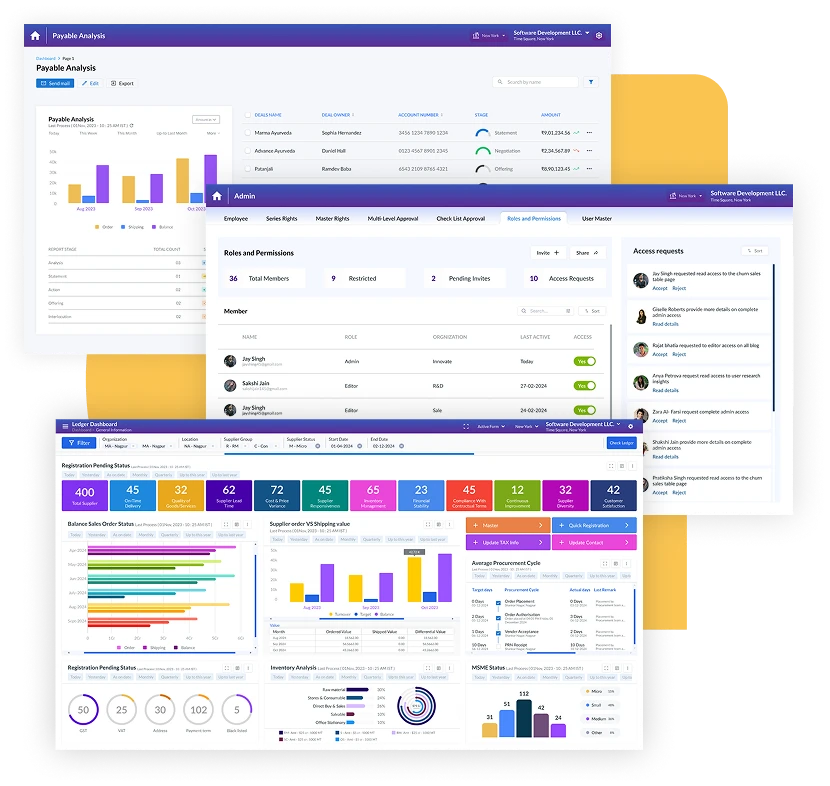

Enhanced Operational Efficiency

Automate and optimize workflows across production, quality, and inventory management.

Improved Quality Control

Ensure every Raw material to Finish Goods batch meets rigid quality standards, building trust with your customers.

Informed Decision-Making

Leverage powerful analytics to stay ahead of market demands and optimize profitability.

Scalability

Prepare for future growth with a flexible, robust ERP system designed to adapt to your evolving needs.