INDUSTRY SPECIFIC WEB & MOBILE APP SOLUTIONS

Ethanol Manufacturing Industry

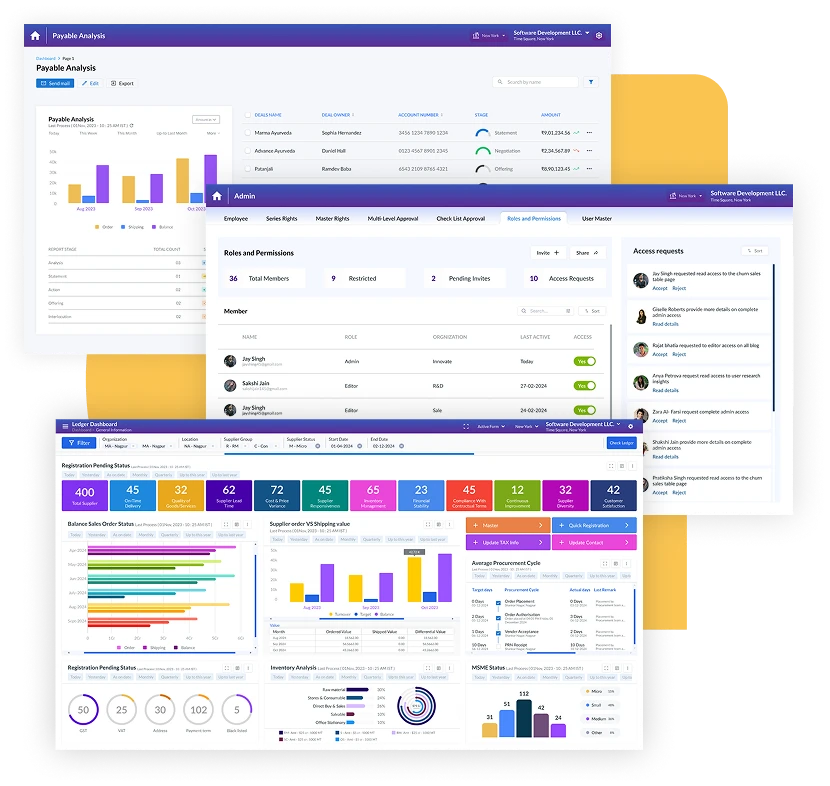

Projense ERP streamlines production planning, enhances process control, and ensures quality improvements tailored for ethanol manufacturers. With seamless integration of inventory and accounting systems, our solution offers real-time insights and efficiency. Partner with us to achieve operational excellence, maintain top-quality production, and drive sustainable business growth.

Let’s innovate together!

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)