.webp)

.webp)

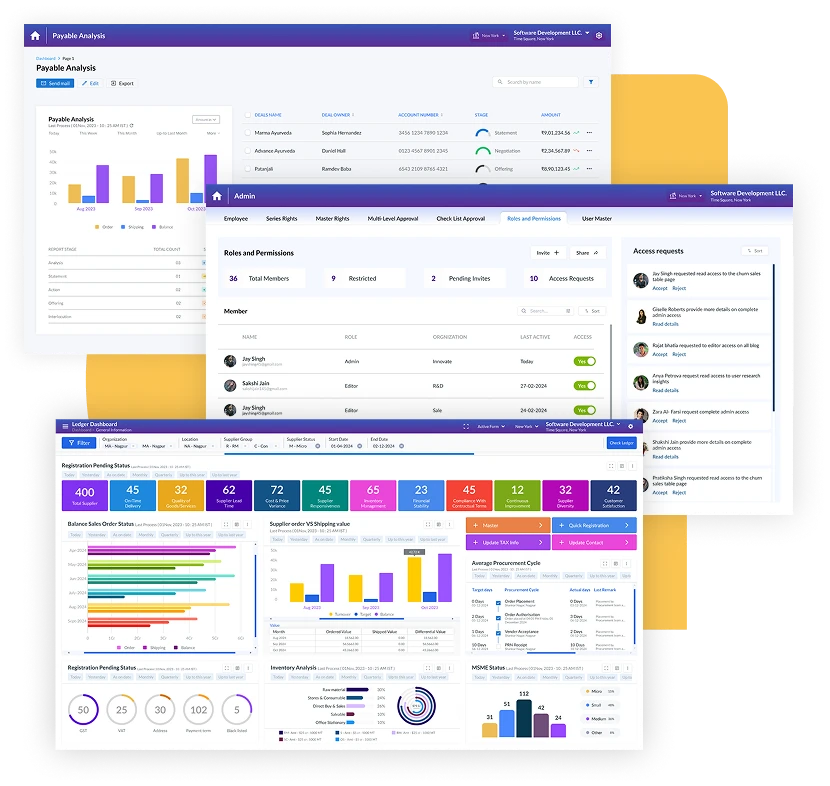

At Projense Systems, we deliver a purpose-built ERP solution designed for steel processing and fabrication workflows, from job estimation to final dispatch. Our system enables accurate job costing by tracking real-time consumption of materials, labor, and machine usage—giving you full visibility into each job’s profitability. With production planning and routing, you can schedule operations more efficiently, minimize changeovers, and reduce idle time across CNCs, press brakes, welding bays, or laser cutting machines. For every fabricated part, our multi-level BOM and routing modules ensure process consistency and reduce errors.

In terms of material and resource optimization, our ERP helps manage raw materials, WIP, and finished goods with batch-level inventory tracking. Built-in tools monitor scrap generation, offcut reuse, and reorder levels to reduce material costs. Preventive machine maintenance ensures lower downtime and improves asset performance. Procurement modules support vendor comparison, rate tracking, and PO automation, ensuring timely and cost-effective sourcing. These features collectively reduce waste, prevent overstocking, and improve production efficiency.

On the business operations side, Projense ERP includes financial integration, automated VAT/GST/TDS compliance, and built-in quality control with rejection analysis. Managers and decision-makers can access real-time dashboards to monitor cost-per-job, production KPIs, and project-level margins. The system connects the shop floor to finance and operations, ensuring end-to-end process visibility and fewer manual interventions. Whether you're managing custom fabrication or bulk projects, Projense ERP empowers you to run lean, stay compliant, and scale confidently.

Sales & Order Management

Production Planning & Control

BOM & Process Routing

Inventory & Material Management

Quality & Inspection

Job Costing & Estimation

Machine & Maintenance Management

Finance & Accounting

HR & Workforce Management

Project & Job Tracking

Compliance & Document Management

Steel processing and fabrication operations are complex, requiring tight coordination of inventory, production, quality control, and delivery timelines. Projense ERP is purpose-built to handle these challenges with precision and scalability. It supports operations such as slitting, shearing, laser cutting, bending, welding, galvanizing, and assembly-while ensuring full traceability of coils, plates, bars, and fabricated components.

With integrated tools for nesting optimization and CNC machine communication, Projense ERP minimizes material scrap and downtime. Real-time visibility into shop floor activities, combined with intelligent production scheduling, allows managers to respond quickly to changing demands and maintain high throughput.

.webp)

The system also manages essential functions like heat number tracking, certification compliance (ISO, ASTM, etc.), inspection records, and quality audits-all centralized for easy access during audits or customer inquiries. Whether you operate as a service center, job shop, or contract fabricator,

Projense ERP equips your business to deliver consistently high-quality steel products, on time and within budget.

.webp)

Your trusted guide -

Projense ERP is tailored to meet the specific needs of the steel processing and fabrication sector, offering robust tools that streamline operations, enhance production planning, and ensure compliance with industry standards. Its modular design supports customization, enabling companies to manage everything from inventory to job costing with precision. With real-time data access and workflow automation, Projense ERP reduces manual intervention and increases operational efficiency.

Whether you're handling complex fabrication projects or high-volume processing, Projense ERP delivers the agility and control needed to stay competitive.

Key Benefits

Projense ERP empowers steel processors and fabricators to take control of their entire operation - from raw material intake to finished product delivery.

By unifying critical business functions in a single, intuitive platform, Projense eliminates inefficiencies, reduces manual errors, and enables smarter decision-making. Whether you're managing complex custom jobs or scaling up production,

Projense ERP provides the tools and insights needed to streamline workflows, optimize resource use, and drive sustainable growth.

Steel processing and fabrication companies can boost operational visibility, streamline job planning, and tightly manage costs with Projense CRM—built to handle complex fabrication workflows and ready to shape your future.

.webp)

Lead & Inquiry Management

Track inquiries by material, size, and process, segment leads by industry, and manage follow-ups with a stage-wise lead scheduler.

.webp)

Quotation Management

Generate process-based quotations with version control, margin visibility, and streamlined approval workflows.

.webp)

Order & Dispatch Tracking

Manage order revisions with approval logs, send dispatch updates via email/SMS, and maintain customer-specific specs and drawing archives.

.webp)

After-Sales & Complaint Handling

Log complaints related to fit, weld, or spec mismatches, resolve them within SLAs, and track credit notes or remakes efficiently.

.webp)

Marketing Campaigns

Run industry-specific campaigns, track leads from events and trade shows, and manage follow-ups via bulk email, WhatsApp, and calls.

.webp)

Customer Analytics

Analyse revenue and margins by customer or segment, track sales conversions and lost opportunities, all through integrated ERP-CRM dashboards.

Steel Processing & Fabrication looking to improve production flow, reduce material waste, and keep a close eye on quality can rely on Projense ERP. Our solution is designed for the industry, helping you gain better control, work more efficiently, and increase overall profitability.

Get industry-specific insights and updates from our experienced specialists delivered to you regularly.

Ensure global data compliance with secure, encrypted, and governed data management.

.webp)

Industry 4.0 boosts packaging with AI, IoT, automation, and efficiency.

Projense Systems is committed to delivering future-ready, customer-centric software solutions with an unwavering focus on quality, innovation, and excellence in software development and implementation.

Get in touch today for a personalized software implementation consultation with our expert team! Let’s transform your ideas into powerful, innovative solutions and drive your success forward.

Join the other exporters and importers who get the latest news, tips and insights from international trade professionals.